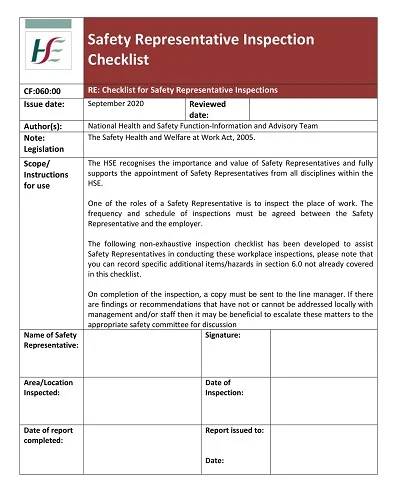

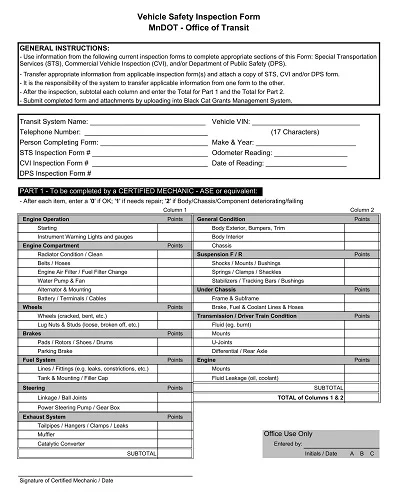

A Safety Inspection Checklist Template refers to a list normally tendered through which various aspects of safety compliance in different places can be achieved. It is a list of safety items, conditions, and practices that must be ascertained and usually reflects the safety items, conditions, and practices particular to an industry or activity.

This template assists in the following aspects, Hazards – review the equipment to find out things that may cause harm; functioning – check whether the equipment is in good working condition, presence of safety procedures, and finally, whether safety procedures have been understood. Companies deem it suitable for exercises such as preventive and corrective measures that reduce accident occurrence and adherence to regulatory requirements.

Download Free Safety Inspection Checklist Templates

What is a Safety Inspection Checklist?

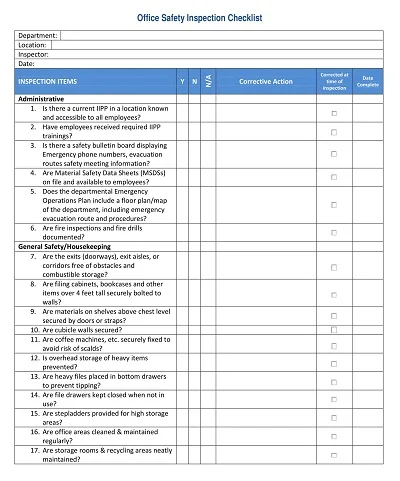

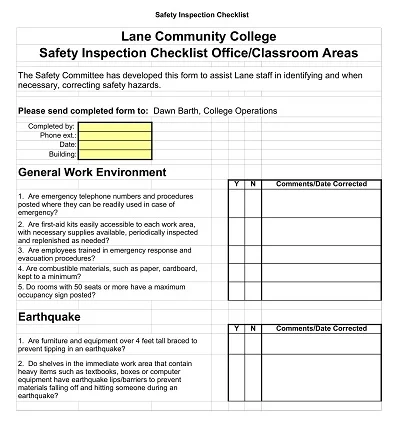

A Safety Inspection Checklist is a document that facilitates the identification of compliance with laid-down safety measures by safety officers and other related personnel when in functional spaces. This list is systematic in that it contains several elements that describe the state of equipment and the environment, signages, hazards that may be present in the area, and references to safety policies.

Reducing risk factors by visiting the checklist regularly would help avoid potential threats and act accordingly to ensure the security and safety of people at the premises.

Types of Safety Inspections

A safety inspection is a definite and important element that concerns the safety of the working environment and business performance. Here, we examine several different types of safety inspections:

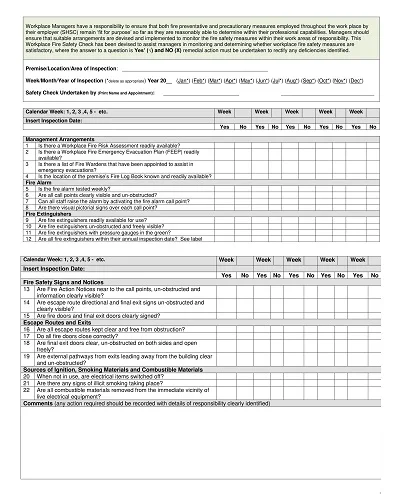

Routine Safety Checkups

These are the common types of checks that are carried out regularly or at specified intervals of time. They check that the tools work, that safety measures have been applied, and that nobody has added new risks since the last inspection.

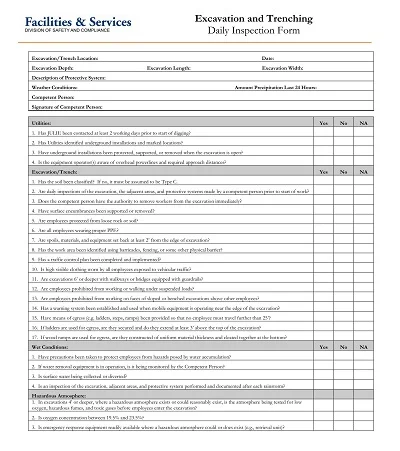

- Daily Inspections: Deceptive optical examinations or investigations are carried out daily.

- Weekly Audits: Larger inspections to reinvestigate in search of any loopholes or minor concerns that the initial inspection turned a blind eye to.

Comprehensive Inspections

They extensively evaluate facilities, equipment, systems, activities, and safety procedures and usually involve professional safety officers. They intend to discover previous drawbacks not detectable when giving regular visits.

- Periodic Scheduled Inspections: They happen tactfully and have a time frame to be met, usually in sync with regulations or company guidelines.

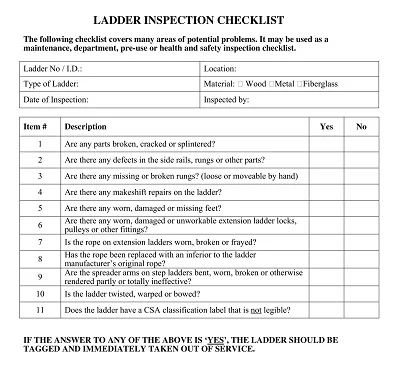

- Preventative Maintenance Inspections: One should not neglect any piece of hardware and its proper maintenance to ensure they do not break down midway or cause an accident.

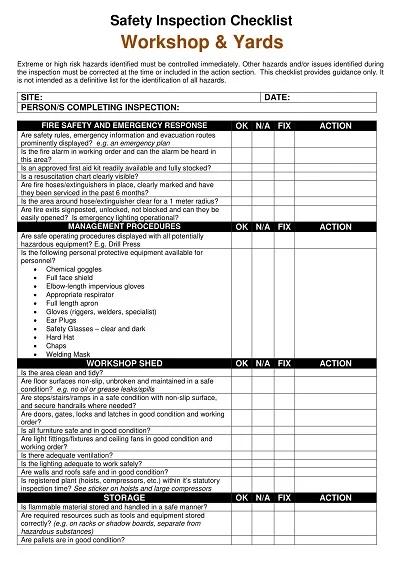

Specialized Safety Assessments

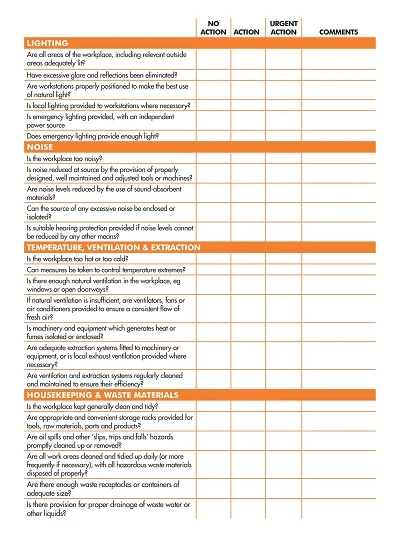

These assessments focus on particular aspects of workplace safety, such as:

- Ergonomic Assessments: Assessing computerized workstations and occupational activities to minimize stress and the onset of movement-related disorders.

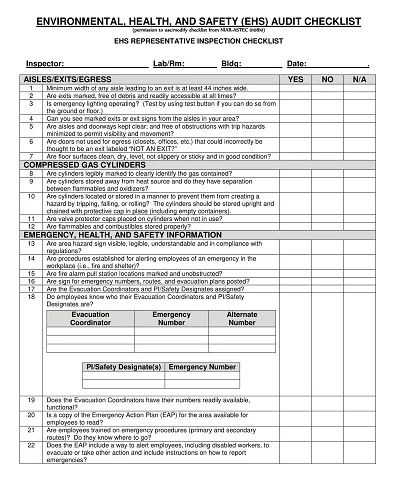

- Environmental Assessments: Searching for contaminants that may be hazardous to people, the environment, or other unhealthy factors.

Investigative Inspections

An investigative-type inspection is typically carried out when there is an occurrence or likelihood of an occurrence, and it is aimed at identifying the cause of the occurrence so it does not repeat itself.

- Accident Investigations: The current paper undertakes a detailed investigation of the steps that follow an accident to identify flaws and failures.

- Hazard-Specific Inspections: In case a particular danger is detected, an assessment will be aimed at searching both for the nature of the threat and its minimization.

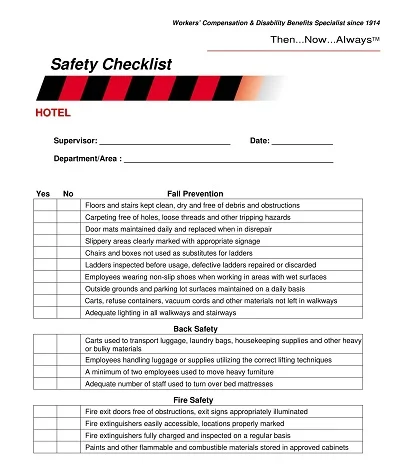

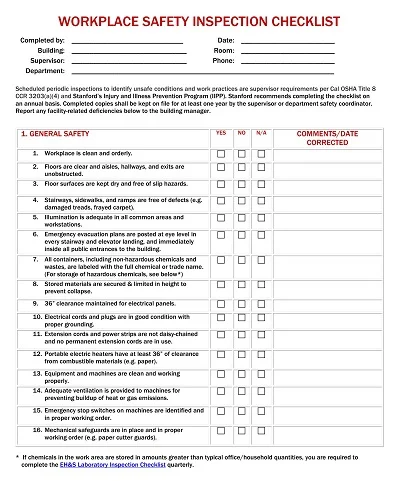

Regulatory Compliance Inspections

They help underscore whether the schools, facilities, office complexes, or other buildings adhere to regional, state, and national laws. They are particularly renowned for being structured and directed through the requirements of the oversight bodies.

- OSHA Inspections: An investigation was done by the Occupational Safety and Health Administration to ascertain whether the subject complied with the health and safety measures at the workplace.

- Environmental Compliance Inspections: To ensure compliance with environmental standards set in the laws and working regulations.

Therefore, one should comprehensively grasp different types of safety inspections to congratulate an acceptable safety culture and the well-being of all organization stakeholders.

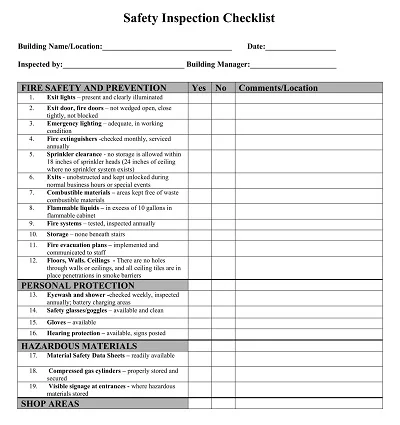

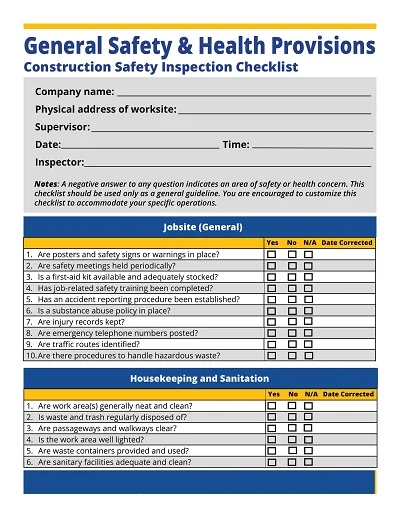

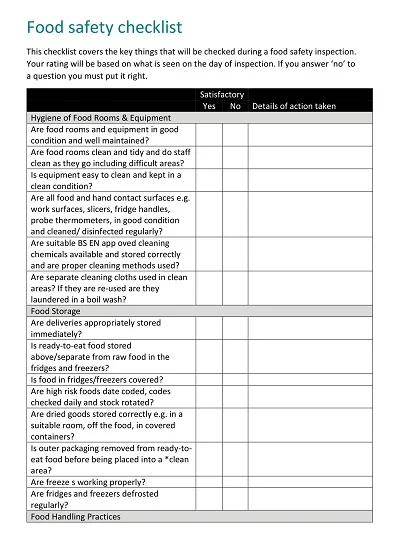

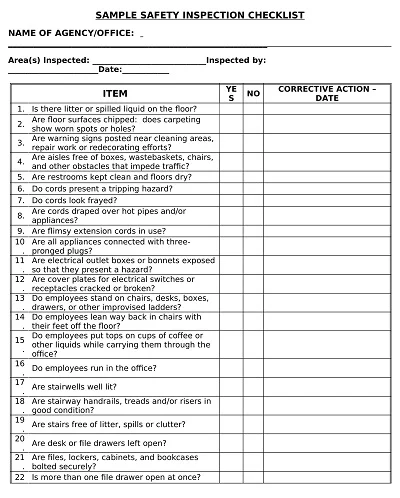

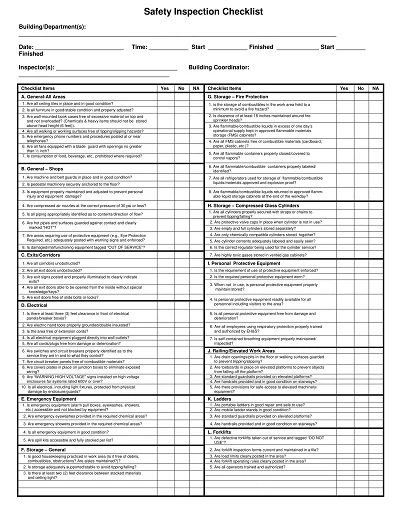

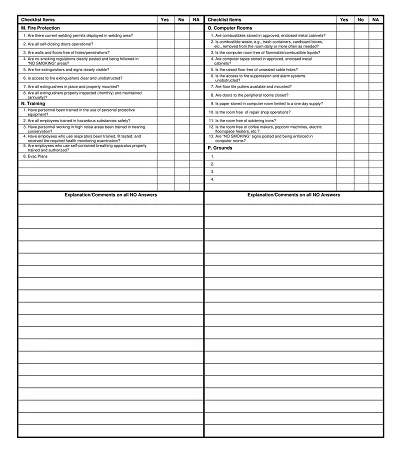

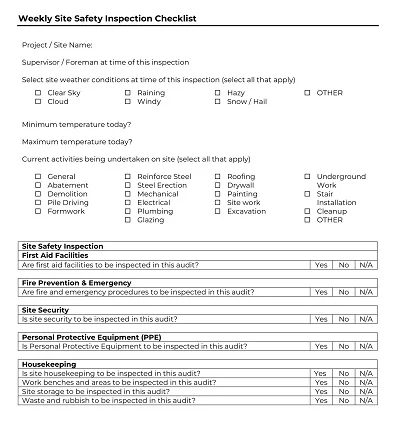

Components of a Safety Inspection Checklist

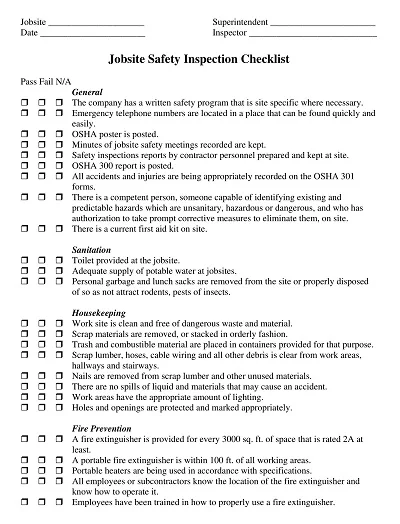

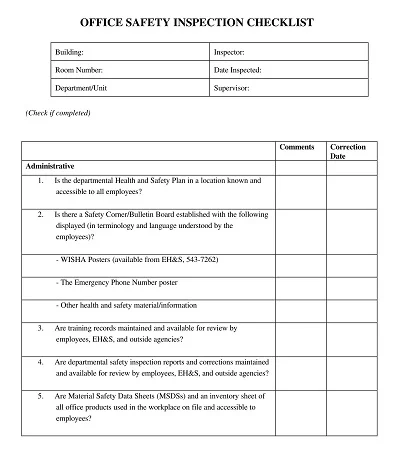

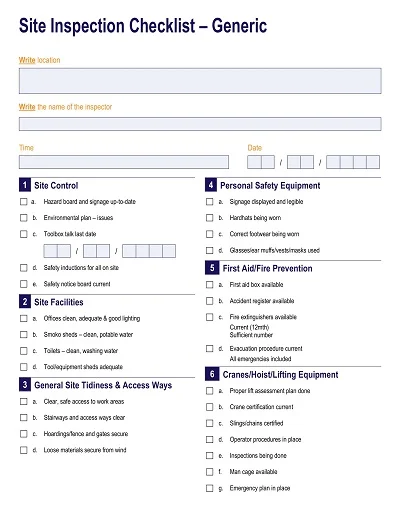

Some of the components that accompany the checklist must include some of the following essentials to give a general outlook of the environment or workplace that needs to be inspected. Key categories might include:

- Personal Protective Equipment (PPE): Check on the availability and condition of general and specialized PPEs fit to be used for particular tasks.

- Fire Safety: Test fire extinguishers and alarms and check that sprinkler systems are in order while ensuring fire exits are clearly labeled and their passageways are not obstructed.

- Electrical Safety: Ensure all electrical appliances function correctly and check the suitability of the cords and outlets without exposed wiring.

- Hazardous Materials: Whenever dealing with chemical or other dangerous materials, recommend storage and handling procedures that meet Material Safety Data Sheets.

- Emergency Procedures: Update all staff members on the procedures that require being followed and the correct exit routes or assembly points.

- Machinery and Equipment: To ensure that all the machinery in the business functions correctly and safely, one should evaluate all machinery’s maintenance and operation records.

- Housekeeping: Evaluate the tidiness of the place of work. This should include the cleanliness of the area, and the passageways should be clear from obstruction and spillage.

- Safety Signage: Check and confirm that all signs to be present are in place and adequately tell the hazard or the action to be taken.

Safety Inspection Checklists: Unveiling Their Benefits

Here are some benefits of Safety Inspection Checklists:

Enhance Safety

By simply going through a safety inspection checklist, one can learn about overlaps, gaps, or environmental risks before they can lead to an accident. Therefore, this proactive measure protects also the employees, customers, and visitors from any danger that may occur at the workplace.

Compliance with Regulations

These checklists provide companies with an easy way of ensuring they adhere to specific safety standards set by the local and state authorities and, occasionally, the federal governments. Using such lists for regular updates and compliance can help avoid legal consequences and penalties that are bound to crop up due to non-compliance.

Preventative Maintenance

Scheduling helps in inspection to determine whether equipment needs repairs, instead of working and breaking down or even wearing out; this makes work proceed unintermittingly.

Increased Awareness

Workers’ participation in the inspection execution contributes to increased attention to environmental characteristics and respect for the safety policy requirements, which enhances the orientation towards prevention.

Cost Savings

Detecting problems before they arise can prevent the occurrence of negative repercussions, which in turn, can cost an organization lots of money in the form of liabilities. This systematic approach, based on checklists, is a way of being more rational and cost-efficient in managing risks.

Improved Productivity

People’s health and happiness improve when there is a good physical environment at the workplace since they do not stress about getting harmed; thus, performance is improved.

Documentation and Record Keeping

The checklists help document that safety inspection was undertaken and may act as an official record. It can be useful, especially in investigations or insurance claims where it can prove that diligence was made in choosing the supplier through documentation.

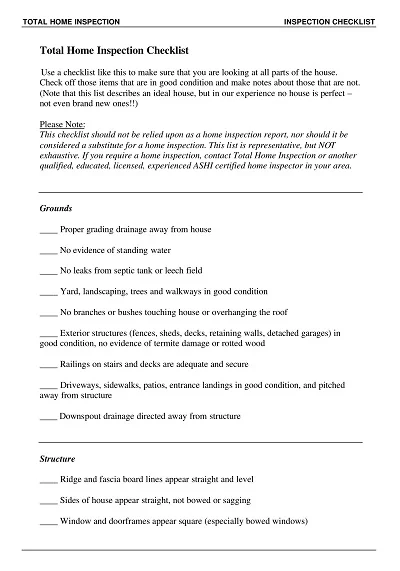

How to Use a Safety Inspection Checklist Template

To effectively use a Safety Inspection Checklist Template, follow these steps:

- Download or Access the Template: Select the template that fits your environment’s specifications or the industry you work for.

- Customize the Template: Add more checklists and mark them on points most suitable for your workplace, certain modes of machinery, or safety.

- Conduct the Inspection: The assessment of the items shall be done by examining each item on the list while physically going around your work area, facility, or site and taking note of any observed things that do not conform.

- Record Findings: In the spaces provided below each aspect on the checklist, note any observation you make or the possibility of risk, impairment, or non-adherence to the requirements being checked.

- Take Corrective Actions: Rank the found problems and develop the necessary corrective measures and preventive actions, be it individual or teamwork, with deadlines if required.

- Review and Update: Being a checklist ensures that you go through this check periodically to check on its efficiency when there has been a change in processes, new equipment placed, or after an occurrence that may affect safety requirements has happened.

- Train Your Team: Make certain all personnel within the team comprehend how to run the checklist and the significance of undertaking sufficient levels of precaution during safety assessment activities.